How an Extreme Machine is Causing a Stir in Bremen

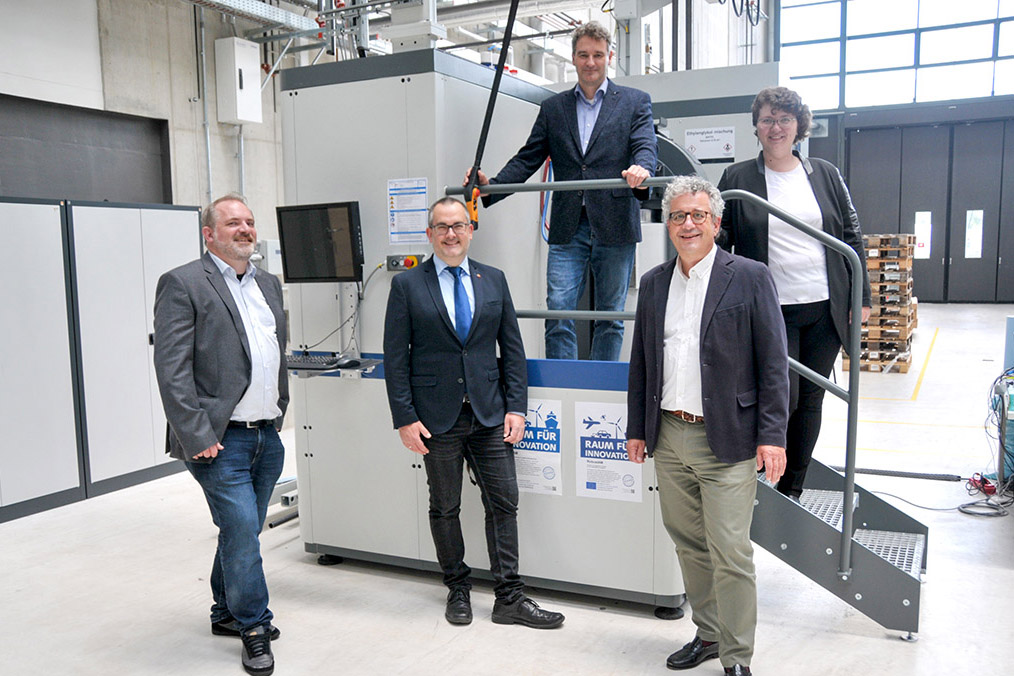

Happy about the new device: Bastian Müller, Ministry of Economic Affairs, Labour and Europe, Dr. Rainer Fechte-Heinen, Leibniz institute for materials-related technologies– IWT, Dr. Hubertus Lohner, Airbus, Dr. Claudio Dalle Donne, Airbus, Dr. Anastasiya Tönjes, IWT

When metal components come out of the 3D printer, they often have to undergo extensive reworking, especially in safety-critical applications such aviation and aerospace. Researchers in the Bremen ECOMAT technology centre are aiming to combine heat treatment and aggregation in a single process step, using a hot isostatic press (HIP) known familiarly as the "HIPpe".

It is an extreme machine: the HIPpe achieves 1,400 degrees Celsius, almost the melting point of iron. And its pressure level of 2,000 bar is equivalent to having a 7 Series BMW pressing down on a finger tip. And all that is contained in a toolbox-sized pressure chamber which is the core of the new HIPpe.

What is a hot isostatic press?

Hot isostatic presses combine heat and pressure to produce components with the required strength, density or ductility properties. Here, the pressure is generated by a gas (Argon), which is applied on the component from all sides, hence the term "isostatic".

The basic underlying principle is certainly not new: people have been using pressure and heat to, for example, modify the strength of metals, for thousands of years. Hammering and then quenching red-hot iron in a smithy is an obvious example. Hot isostatic presses refine this process, for use in modern industrial applications. They were already being used for metals, ceramics, composite materials or during sintering (creating workpieces from powders) more than 50 years ago. Using them, exactly the required material properties can be specified, according to how much pressure and temperature they produce.

The HIP opens up new possibilities for 3D printing applications

Hot isostatic presses in additive production

Additive manufacturing is a new application area for these presses. Fine pores are produced as a result of the 3D metal printing process, and act as unwanted fracture points in the material.

These pores are a safety risk, especially in aircraft construction, as cracks can form there under load. If 3D-printed components are to take to the air, they have to undergo extensive reworking, for that reason. When the HIPpe is used, these pores can be closed, using a combination of pressure and heat.

"The HIPpe enables us to eradicate every last bit of residual porosity in components and specify required properties such as strength or ductability exactly, at the same time", explained Dr. Anastasiya Tönjes. Lightweight Construction Materials Section Leader at the Bremen Leibniz-IWT (institute for materials-related technologies). "When we use the HIPpe, the combination of heat and pressure not only closes the pores but also adjusts the internal structure so no subsequent heat treatment is necessary. This has both cost and ecological benefits."

ECOMAT: a benefit for aviation and aerospace located in Bremen

Tönjes and her team are researching using the new HIPpe in the Bremen ECOMAT technology centre. She is especially interested in titanium alloys, and also aluminium alloys: the metals used most frequently in 3D printing for aerospace applications. Their aim: to improve materials for lightweight construction and optimises production processes.

"There are no more than a handful of these devices in Germany. The new HIPpe in ECOMAT gives us a real locational competitive advantage. For that reason, we are always pleased if companies approach us and want to work with us to research the possibilities that the technology offers. In that respect, we are also attracting huge interest from outside our region", said Dr. Tönjes.

By the way, the Bremen HIPpe has another impressive trick up its sleeve: the maximum cooling speed of pressure vessels is around of 3,000 Kelvin (or degrees Celsius) per minute. The temperature shock quenches the hot metal extremely quickly, affecting its mechanical properties. "How does the component change in this process? And how can we use that for a large-scale industrial application? We are researching that here at ECOMAT", said Dr. Tönjes.

Hot isostatic press in ECOMAT

[ More News ]